Product Description

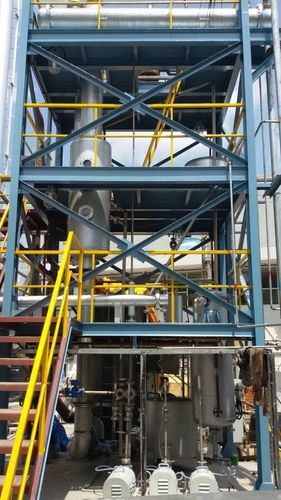

We are a note-worthy manufacturer and supplier of a wide gamut of Forced Circulation Evaporators. Our evaporators are designed employing advanced technology in our sound infrastructure unit. Owing to their compact size, easy installation and high working efficiency; our evaporators are well acclaimed in the market. Clients can avail these evaporators in various sizes and specifications from us as per their requirements. Itis widely being used for processing liquids in pharmaceutical, textile and chemical industries.

Forced Circulation EvaporatorsAttributes:

- Immaculate performance

- Available in customized and tailor made form as well.

- Less lower consumption power require

- Easy installation and handling evaporator plant

- Pocket friendly prices of circulation evaporator

Technical Parameters

|

Product Type:

|

Evaporator

|

|

Evaporation Process:

|

Vacuum Distillation

|

|

Voltage:

|

As per equipment requirement

|

|

Dimension(L*W*H):

|

Vary from equipment

|

|

Circulation Evaporator Weight:

|

Vary according equipment requirement

|

|

Evaporation Type:

|

Falling film evaporation

|

|

Evaporator Effect No.:

|

Double-effect

|

|

Heating Source:

|

Steam type

|

Specifications

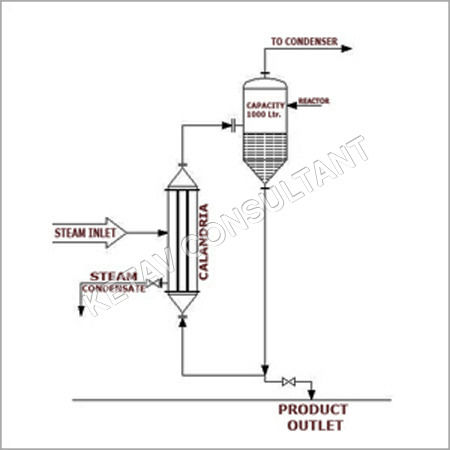

- In our forced circulation evaporator, the liquids are charged with increased velocity by way of tubes. Vapor is formed by the flashing liquid owing to the slight difference in absolute pressure of separator and tube bundle.

- Ideal for material that can easily foul the surfaces of heat transfer as well as the surfaces where crystallization occurs.

Working

In the mentioned evaporator, pumping of liquor is done from the bottom of the system using tubes of heat exchangers. During this process, heat is added into the evaporator tank to maintain enough height of liquid above the level of liquor. This helps in the prevention of precipitation process that otherwise can cause fouling of the surface used for transferring heat.

Key Points:

- Circulation pump helps in determining the velocity flow within the tubes resulting in optimization of heat exchanging surfaces.

- Find usage in the application that use highly viscous liquids or the ones that have fouling tendency

- The process of evaporation is carried out in the separator and this results in the reduction of fouling

- Useful during the process of crystallization of saline solutions

These Forced Circulation Evaporators utilize automatic PLC control systems, ensuring precise management of temperature, flow, and process parameters for optimal results. The electric drive provides consistent reliability and ease of operation, making it suitable for various industrial applications.

Robust Stainless Steel BuildManufactured exclusively from stainless steel, the evaporators guarantee durability and corrosion resistance, even under challenging conditions and aggressive substances. This material choice enhances product longevity, hygiene, and safety, meeting stringent industrial standards.

FAQs of Forced Circulation Evaporators:

Q: How does the PLC control system optimize the operation of forced circulation evaporators?

A: The PLC control system automates processes such as temperature regulation, flow rate adjustments, and safety interlocks, ensuring precise and efficient evaporation with minimal manual intervention.

Q: What materials are used in the construction of your forced circulation evaporators?

A: Our evaporators are made from premium-grade stainless steel, providing durability, corrosion resistance, and compliance with industrial hygiene requirements.

Q: When should I consider using a forced circulation evaporator in my process?

A: Forced circulation evaporators are ideal when handling high-viscosity liquids or processes requiring rapid and uniform heat transfer, commonly used for concentration and purification in chemical, pharmaceutical, and food industries.

Q: Where do you supply and export forced circulation evaporators?

A: As a comprehensive solution provider based in India, we supply, export, import, and manufacture forced circulation evaporators for clients worldwide, offering reliable support and services.

Q: What is the typical process involved in operating these evaporators?

A: The liquid is continuously circulated by an electric pump through a heat exchanger, where it is heated and vaporized. The PLC control system regulates all parameters, ensuring consistent and efficient evaporation.

Q: How is the evaporator installed and what voltage ranges are supported?

A: Installation is straightforward and can be adapted to diverse plant layouts. Our machines support a wide voltage range from 120V to 440V, ensuring compatibility with various power supplies.

Q: What benefits does your product offer over standard evaporators?

A: Our forced circulation evaporators deliver faster processing, enhanced energy efficiency, automated control for reliability, improved safety, and lower maintenance, complemented by a one-year warranty for assurance.