Call Us08045812114

- Home Page

- Company Profile

-

Our Products

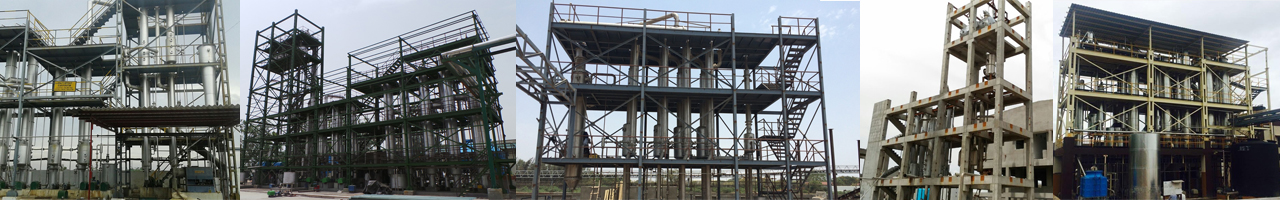

- Multiple Effect Evaporators Plants

- Multiple Effect Evaporator For Pharma Industries

- Mechanical Vapor Recompression (MVR)

- Falling Film Vaporizers

- Film Dryers

- Multiple Effect Evaporator Plant For Textile Ind.

- Multiple Effect Evaporator Plants

- Wastewater Evaporation Plant

- Salt Recovery Evaporation Plant

- Product Concentration Evaporator Plant

- Multiple Effect Evaporator With Crystallizer Plant

- Multiple Effect Evaporator For Pesticide Industries

- Multiple Effect Evaporation System with ATFD

- Multiple-Effect Vacuum Evaporator

- Falling Film Evaporator Plant

- MEE Plant

- Evaporator Plants

- Falling Film Evaporator

- Dextrose Concentration Plant

- Fruit Concentration Plants

- Milk Concentration Plant

- Forced Circulation Evaporators

- Natural Circulation Evaporators

- Plate Type Evaporator

- Evaporator Plant For Pharmaceutical Industries

- Evaporator Plant For Pesticide Industries

- Multiple Effect Evaporator For Automobile Industry

- Evaporator Plants For Milk Industries

- Evaporator Plant For Automobile Industries

- Heat Exchanger

- Wastewater Treatment Plant (WWTP)

- Jet Ejectors

- Tube Condenser

- Crystallizer Plants

- Agitated Thin Film Dryer

- Effluent Treatment Plant

- Distillation Plants

- Reverse Osmosis Plant

- Anti Foaming Chemicals

- Anti Scaling Chemical

- Caustic Recovery Plant

- Titanium Tubes

- Zero Liquid Discharge Evaporator Plant

- Descaling Chemicals

- Vapor Separator

- Water Pollution Control System

- Vacuum Boosters

- Pusher Centrifuge

- Solvent Recovery Stripper System

- Stainless Steel Vapor Separator

- Silicone Defoamer

- Water Recycling System

- Scrubber System

- Zero Liquid Discharge System

- Effluent Recycling Plant

- Nanofiltration

- Membrane Bio Reactor

- Industrial Dryers

- Zero Liquid Discharge Plant

- Heat Exchanger Condenser

- Multiple Effect Evaporators Plants

- More Info

- Contact Us