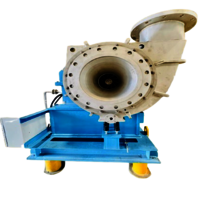

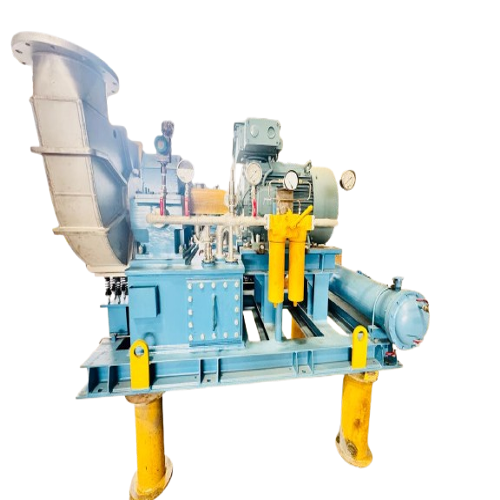

Product Description

Buy from Mechanical Vapor Recompression (MVR) for your industrial processes, like distillation and evaporation. The process followed in this equipment is called an energy recovery process, as it condenses energy from a low-pressure vapor by the way of compression. This process results in small volume of vapor/liquid at a higher temperature and pressure. This process is necessary for waste heat recycling and thereby improving efficiency. The resultant compressed vapor can again be used to heat the mother for producing more vapor or steam. The condenser heat is recovered and utilized in the evaporation process. This equipment is ideal for use in , chemical, sugar, brewing and many other industries.

Specification

- Energy Saving: 80 - 98%

- Voltage: 220V - 440V

- Automatic Grade: Automatic

- Frequency: 50/60 Hz

- Range: 80-98%.

- Power Source: Electric

Efficient Industrial Vapor RecoveryThe MVR system harnesses mechanical vapor recompression technology to recycle vapor in industrial processes such as evaporation, concentration, and distillation. Its stainless steel construction and adaptable electric voltage range ensure robust and energy-efficient operation. This system is ideal for industries seeking to reduce energy costs and maximize process compatibility.

Versatile Application and Reliable SupportDesigned to accommodate vast industrial spaces with large dimensions and flexible widths, this MVR can be integrated into new or existing process lines. As a supplier and service provider across India, we offer comprehensive installation guidance and a 1-year warranty, ensuring that your investment is fully supported from initiation through operation.

FAQs of Mechanical Vapor Recompression (MVR):

Q: How does the Mechanical Vapor Recompression (MVR) system work in industrial environments?

A: The MVR system operates by compressing and recycling vapor generated during industrial evaporation or concentration processes. This mechanism uses electric-powered compressors to increase vapor pressure and temperature, enabling it to be reused as heating steam. This approach significantly reduces overall energy consumption and enhances process efficiency.

Q: What industrial applications are suitable for this MVR unit?

A: This MVR unit is ideal for industries requiring large-scale evaporation, concentration, or distillation, such as chemical processing, pharmaceuticals, wastewater treatment, and food production. Its robust stainless steel construction and wide voltage compatibility make it reliable for continuous, demanding operations.

Q: When should I consider using an MVR system instead of a traditional evaporator?

A: An MVR system is recommended when energy efficiency, operational cost reduction, and minimal environmental impact are key considerations. If you have high energy consumption in evaporation or concentration processes, switching to MVR can provide substantial benefits, especially for continuous and large-volume applications.

Q: Where is this MVR system manufactured and supported?

A: Our MVR system is manufactured and supplied in India, with full support for export, import, after-sales service, and installation across the country. We cater to industrial clients nationwide, ensuring accessibility and technical assistance wherever required.

Q: What is the process for installing and commissioning the MVR system?

A: Installation typically involves site assessment, alignment with process requirements, electrical connection (120440 Volt), and mechanical integration. Our technical team provides step-by-step guidance, from initial setup to commissioning, ensuring seamless operation and adherence to industry standards.

Q: How is the MVR system maintained, and what warranty coverage is provided?

A: The stainless steel construction simplifies maintenance, requiring only periodic inspections and minor servicing of moving components. We offer a comprehensive 1-year warranty covering manufacturing defects and technical issues. Our service team is available to provide support and maintenance throughout the warranty period.

Q: What are the key benefits of adopting this MVR system for industrial use?

A: Adopting this MVR solution results in significant energy savings, reduced operational expenses, improved process sustainability, and enhanced equipment longevity. Its versatile design, reliable stainless steel build, and comprehensive support make it an excellent choice for businesses seeking to boost productivity and environmental responsibility.