Showroom

Our supreme quality Multiple Effect Evaporators Plants are appreciated for their high evaporation intensity and high heat transfer coefficient that is suitable for materials which produce crystals during evaporation. These plants are majorly used in industrial applications such as water desalination, salt production, etc where large volumes of water have to be evaporated.

We offer supreme quality Evaporator Plants for applications related to fluids in various industries such as pesticides, beverage, pharmaceuticals, automobile, etc. Our ergonomically designed plants are known for their longer service life and high quality outputs. These are majorly used used to turn the liquid form of a substance such as water or other fluids into its gaseous-form or vapor.

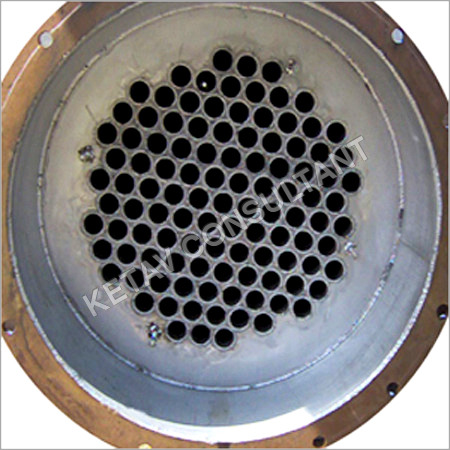

Heat Exchangers are used to transfer heat generated by mechanical or electronic device between a liquid and solid or between two or more liquids to prevent mixing. These are majorly used in sewage treatment, refrigerator, air conditioning, chemical plants, petrochemical plants, petroleum refineries, etc. The exchangers are robust in design and have longer working life.

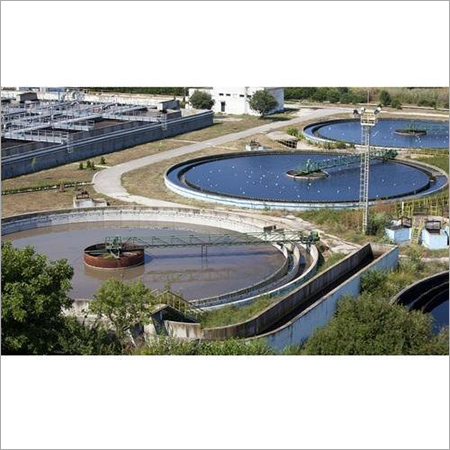

Our Wastewater Treatment Plant is designed and build with accurate dimension and specification for providing the best solution for treating the waste waster of industrial, commercial factories, household drainage etc into clean and safe water. The system consist of different components and process for effective consequence.

Our Jet Ejector are widely used by textile industries. These turn a very large proportion of weak lye into reusable concentrated caustic soda that is strong lye. The recovery plants are rugged in construction and have longer working life. Some other industries which use our plants are Chemical industry, pulp and paper, polyester production, petrol refineries, etc.

The Tube Condensers are used for exchanging of the gases for the system for effective cooling. These are highly useable for using in refrigerator, air cooling, freezing chambers etc. the condensers have modern and reliable designing for providing high level output results.

Our supreme Crystallizers Plants are used to perform solid-liquid separations by heat and mass transfer. These are widely used during the processing process of fertilizers, chemicals, paints, etc. The plants are technologically advanced with various attributes such as user friendly operations, simple installation, reliability, durability, corrosion resistance, power efficiency, low at maintenance, etc.

Agitated Thin Film Dryer is widely used for effective drying of edible items, textile products, medicinal items and chemicals. It helps to vaporize water content or solvent amount from a specific product to obtain its flake or dry powder form.

Our Effluent Treatment Plant is used for reduction of biological oxygen and carbon oxygen demand. These helps in maintaining pH in the surrounding. The plants treats water for making it colorless and odorless and recycle the waste water. They are based on zero or minimum discharge thus are very effective. Our plants are rugged in construction and have smooth running operations.

The process of distillation includes removing of impure substances and components from a liquid based mixture. This process makes use condensation and boiling for doing the aforesaid work. Distillation Plants finds application in various purification of liquid mixture is needed.

This effective use of Reverse Osmosis Plant assists in water purification and water softening. This plant boasts of having very simple maintenance. This plant holds this great capacity to supremely remove bacteria, organic chemicals, lead particles, etc., from polluted water.

Anti Foaming Chemicals finds tremendous use in industrial applications as these help in prevention of forming foams. These chemicals assist in attaining high washing effectiveness. Provided chemicals are rightly formulated and high in quality. These chemicals have high capability to perform in changing industrial environments.

This Anti Scaling Chemical is used for prevention of scaling process and if it is not able to stop scaling process, this chemical, lessens its process of elements, which are scaling in the passage ways and membranes. Provided chemical finds application in industries where utilization of natural waters for machine operation is extreme.

This Caustic Recovery Plant is basically a multi-effect based evaporation plant. Provided plant is utilized in a caustic recovery process. This high energy efficient plant can recover weak lye and transform it to strong lye. This low cost maintaining plant is highly smooth in functioning.

Titanium Tubes are used for designing aerospace engine parts, aircraft hydraulic system etc. These are also used for medical implantation purpose. Seamless design, light weight and good heat transferring capacity are their main aspects.

Our high grade Zero Liquid Discharge Evaporator Plants are used to transmit heat across the surface and condense vapor into liquid. These are used in various industries such as Textiles, Dyes Intermediates, Chemical, Pharmaceuticals, Bulk Drugs, beverage and so on. The plants helps in treating and recovering valuable products from waste with the help of copper tube and shell tube condensers.

Giving priority to diverse needs of clients we offer a range of Descaling & Anti Scaling Chemicals that are used to remove lime deposits from various surfaces such as storage tanks, boilers, heaters, etc. Our chemicals are known for their purity, accurate pH values, compositions, high chemical properties, effectiveness and longer shelf life.

Vapour Separator is extensively used for removing of the water droplets from the steam. This is preferred for their non-corrosive body frame, standard design and great functioning performance. Also, have different function such as cooling, sensing and water separating.

Water Pollution Control System, as the very name suggest finds impressive application in ameliorating quality of wastewater, industrial waste streams and ground water. Provided system that controls water pollution can be used in urban, rural, Peri-urban areas and agricultural landscapes.

Vacuum Boosters are finds quality use in areas where speedy pump downs times are needed. These are needed to boost performance of oil ring, rotating vane and piston pumps. The provided product rises vacuum levels of the backing pumps, thus, resulting in reduction of process temperatures.

This Pusher Centrifuge is a kind of filtration method. It finds application in the separation of slurries containing solids, which filters smoothly. Provided product used uninterrupted filtration operation for fast draining, crystalline, suspended, fibrous or granular solids from liquid phase.

This quality approved Solvent Recovery Stripper System, excellently extracts useful solvents for the purpose of reuse from effluent streams. This process assists in reducing generation of waste. This system assists in doing a very cost-effective solvent reclamation process without any kind of trouble.

This quality approved in design and quality Stainless Steel Vapor Separator, finds massive use for vapor separation in production industries. The separation action is performed swiftly. It comes with an extreme simple operation process. Robust structure of vapor separator makes it a worthy investment.

This high quality based Silicone Defoamer consists of crystalline and solid particles with perfect performance capability of swift suppression and foam breaking in multiple aqueous systems. This product finds massive application in pharmaceuticals, detergents, textiles, paper and pulping industries, etc. It is known for possessing features such as consistent texture, high stability and adequate solubility.

In many industries, huge amount of water is used for performing operational activities, which becomes environmentally damaging. This Water Recycling System, assists in right treating of wastewater and making it perfect for reuse. Recycled form of water assists in reducing pollution by diminishing the amount of wastewater.

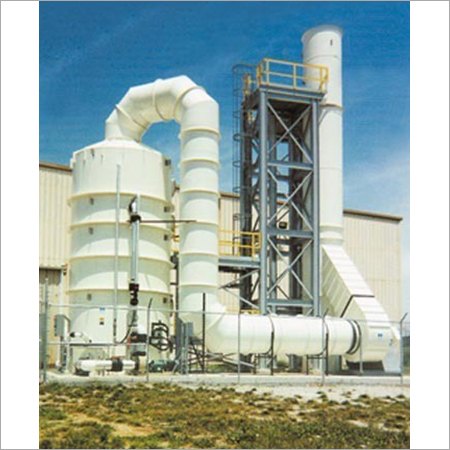

Scrubber System finds use in controlling air pollution as it removes noxious materials industrial based exhaust gases before their release in the environment. This system holds the power to excellently handle several flammable and explosive gasses in a safe manner.

Zero Liquid Discharge Systems are used for handling harsh wastewater. These systems have above 95% recovering capacity. Long service life, low maintenance design and user friendly mechanism are their main aspects.

This array of Effluent Recycling Plants plays significant role in minimizing environmental pollution. High output, low production charge, standard safety features and low installation cost are the key features of such plants.

Nanofiltration systems are used for obtaining germs free pure drinking water. Certified by CE, these plants are known for their high productivity, low production cost and less downtime. These systems are user friendly.

Membrane Bio Reactors can be availed in different membrane area, dimension, micropore size and other specifications based choices. Usually, these have maximum 10 m2 membrane area. Ph level of such reactors ranges between 2 to 13.

"We are mainly dealing in India, Oman, Dubai, Saudi Arabia and U.A.E."