Product Description

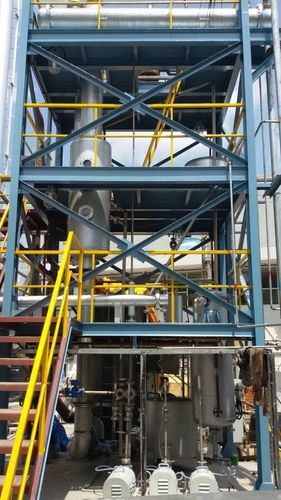

Known for following ethical business policies, our firm specializes in manufacturing and supplying superior quality Falling Film Evaporator. Offered evaporator is designed using latest cutting edge technology under the vigilant supervision of expert professionals. Our evaporator is widely acclaimed by the clients for its superb attributes like consistent performance, high operation efficiency and longer service life. We offer this Falling Film Evaporator in various sizes and specifications so as to meet the varied industrial demands.

Features :

- Excellent heat transfer coefficients.

- Low temperature operation

- Optimum heat transfer area

- Self cleaning action from salting

- Scaling and fouling

Specifications

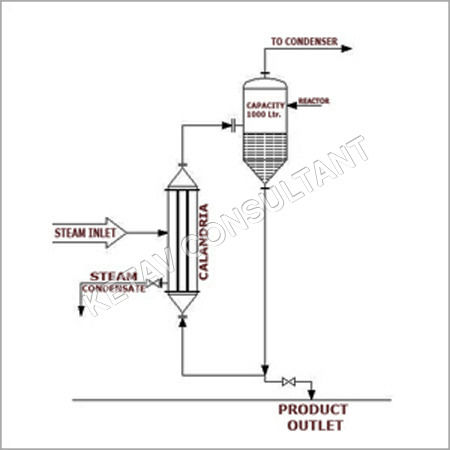

- Preheating of liquid is done to the boiling temperature for concentrating it. In the heating tube, tiny films enter through a distributor connected at the top of evaporator. Then it moves downwards at the boiling temperature that causes it to evaporate partially.

- Falling Film Evaporator works on the principle of liquid-spreading into every tube, hence creating a tiny film all over the tubes area

- Ideal for formulating liquors whose specific heat transfer rate is high

- Also suitable for fluids with low viscosity, less fouling and also for non crystalline solutions.

- Its process is controlled via convection and / or conduction through the film that are two processes for heat transfer

Key Benefits:

- Effects of thermal degradation can be easily minimized using short product contact time

- Because of the heat flux and low temperature of tube wall, fouling can be reduced

- Renders highly efficient performance to allow designs with multiple effects

- Ideal choice for the areas that use heat sensitive products

Working

Bulletined below are the points that describe detailed working of the aforementioned evaporator:

- Top of the exchanger is the place from where the liquid enters that needs to be boiled

- Tubes need to be equally wet and this is ensured by the internal distributor

- A film of liquid is placed along the tube sides for avoiding the tubes from flooding

- While the liquid is passed through the tubes, it is boiled

- Vapor is collected at the bottom of exchanger while the liquid is flushed out

- In most of the cases, this collected vapor find usage for heating the evaporator

Applications :

- Caustic Soda

- Corn Steep-water

- Fruit Juices

- Pectin Solutions

- Pharmaceuticals

- Sorbitol

- Sucrose

Specification

|

Vacuum degree

|

70

|

|

Max Temperature

|

45 Degree

|

|

Design

|

Customized

|

|

Voltage

|

220V/ 380V

|

|

Brand

|

Ketav

|

|

Material

|

Stainless Steel

|

|

Frequency

|

50 Hz

|

High-Efficiency Evaporation ProcessThe Falling Film Evaporator utilizes a thin film of liquid that flows down the interior of vertical tubes, allowing rapid heat and mass transfer. This method ensures efficient evaporation at lower operating temperatures, reducing thermal degradation of sensitive products and improving overall yield. Its design supports continuous operation with minimal supervision needed.

Advanced PLC Control SystemEquipped with a state-of-the-art PLC (Programmable Logic Controller) system, the evaporator enables precise automation of all operational parameters, including temperature, flow rate, and vacuum. This automated control translates to consistent product quality, user-friendly management, and reduced risk of human error during operation.

FAQs of Falling Film Evaporator:

Q: How does the automatic falling film evaporator operate with a PLC control system?

A: The evaporator uses a Programmable Logic Controller (PLC) to automate and monitor key process parameters such as temperature, pressure, and flow rate. This ensures precise, consistent operation, minimal manual intervention, and enhances safety and reliability during continuous production.

Q: What industries commonly use this stainless steel falling film evaporator in India?

A: This evaporator is widely adopted in food processing, chemical manufacturing, and pharmaceutical industries, where gentle yet efficient evaporation is required. Its robust stainless steel construction ensures suitability for handling diverse liquids and corrosive substances.

Q: When should maintenance be performed during the 1-year warranty period?

A: Routine maintenance, including cleaning and checking of electrical components, should be carried out quarterly or as advised in the user manual. This practice optimizes performance, ensures longevity, and keeps your warranty valid for the full year.

Q: Where can this automatic falling film evaporator be installed for operation?

A: It can be installed in industrial production facilities with access to electric power within the 120-440 volt range. The compact, corrosion-resistant design makes it suitable for both large and medium-sized plants across various sectors in India.

Q: What is the process behind falling film evaporation, and why is it beneficial?

A: Falling film evaporation involves a liquid forming a thin film on the inside walls of vertical tubes, where it is rapidly heated and partially evaporated. This process is energy-efficient, minimizes residence time, prevents product degradation, and allows high throughputs with gentle processing.

Q: How is this evaporator exported and supplied across India?

A: As a manufacturer, exporter, and supplier, the company manages logistics to ship the equipment safely to various regions in India. Comprehensive support is offered, including installation guidance and after-sales service.