Product Description

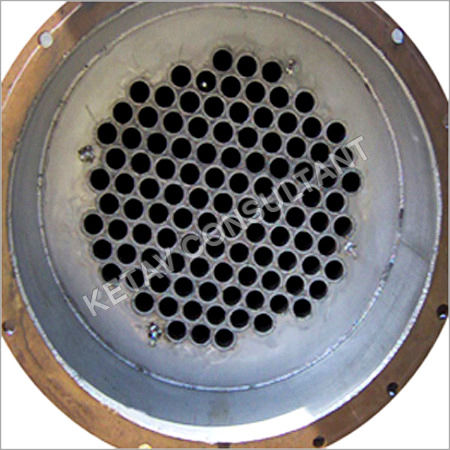

The company is glad to provide reboiler heat exchanger at best market rate. The exchange is necessarily used in gas processing applications. It is manufactured using superior quality materials to match the industry standards. It is a power efficient device and thus, it requires low maintenance costs. With its rugged construction, its durability gets extended. This equipment is known for better transferring heat processes. Reboiler heat exchanger plate maximizes thermal performance. This is demanded in petrochemical industries, air conditioning systems and refining sectors. Being manufactured under specific industrial norms, it is safe for the workers associated. The unmatchable performance has collected praises from our regular clients.

Specifications:

- Pressure: As high as 30 bar

- Tube Material: Steel

- Medium Used: Oil

- Type: Shell and Tube

Application: Food Process Industry, Pharmaceutical industry, Mining and Construction Industry, Hydraulic and Industrial Process, Power Generation

Advanced Thermal EfficiencyThe reboiler heat exchanger excels at providing consistent heat transfer, crucial for industrial distillation and chemical processes. Its tube structure maximizes contact surface area, supporting significant liquid throughput while maintaining system efficiency and safety. This makes it ideal for high-demand environments.

Built for Industrial ApplicationEngineered specifically for industrial use, this heat exchanger meets the rigorous demands of sectors such as chemical manufacturing, petrochemicals, and power generation. Its wide width options and pressure resilience offer customizability and dependability, ensuring it integrates smoothly into existing workflows.

FAQs of Reboiler Heat Exchanger:

Q: How is the reboiler heat exchanger installed in an industrial setting?

A: Installation involves securing the tube heat exchanger within the plants process line, ensuring proper alignment to support the specified liquid flow rate and pressure. Professional technicians typically manage setup and commissioning to guarantee safe operation and compatibility with existing equipment.

Q: What are the key benefits of using a tube type reboiler heat exchanger?

A: The tube structure provides extensive heat transfer surface area, supporting efficient energy use and rapid thermal exchange. Its design allows for reliable operation under high pressures and varying liquid flow rates, reducing downtime and maintenance costs.

Q: When should maintenance be performed on the reboiler heat exchanger?

A: Regular maintenance should be scheduled based on operating conditions, typically every few months in high-use environments. Inspections focus on tube integrity, flow rate consistency, and voltage stability to prevent unexpected failures and optimize longevity.

Q: Where can I source this reboiler heat exchanger in India?

A: You can acquire these exchangers from various exporters, importers, manufacturers, service providers, and suppliers throughout India, ensuring flexibility in procurement and after-sales support.

Q: What is the typical liquid flow rate for this heat exchanger model?

A: This model supports a liquid flow rate of 5 cubic meters per hour per square meter per second, accommodating demanding processing environments while maintaining performance standards.

Q: How does the working pressure of 50 kg/cm benefit industrial usage?

A: A working pressure of 50 kg/cm allows the exchanger to manage heavy-duty applications, handling volatile or high-pressure fluids with enhanced safety and reliability. This robustness makes it suitable for intensive industrial processes.

Q: What processes are supported by this reboiler heat exchanger?

A: Common applications include distillation, thermal vaporization, and the regeneration of process streams. Its flexibility allows for integration into multiple process setups in industries such as chemical production and refining.