Product Description

Backed by enormous experience in this domain, we are instrumental in manufacturing and supplying a qualitative gamut of Shell and Tube Heat Exchangers. As these exchangers are made using premium quality steel, these have high structural strength and longer service life. Owing to their superb features like high surface finish, excellent performance and easy maintenance, our heat exchangers are highly acknowledged in the market. We offer these Shell and Tube Heat Exchangers in various specifications to our clients.

Applications:

- Petrochemical industry

- Power plants

- Air conditioning unit

- Chemical Plants

Types Of Heat Exchangers:

Heat Exchangers & Condensers

Heat exchangers and condensers offered by us are used in various different types of industrial applications. Designed to ensure superior performance, these are compact in design which are very easy to operate and requires less maintenance. Furthermore with the support of active team of professionals, we are offering these exchangers in various custom ordered specifications as well as in standard specifications. Available ta most competitive prices, our range of heat exchangers are made under expert supervision which are tested thoroughly before delivery. Along with this we also offer products such as condenser water pumps, tubular heat exchanger, crystallizer, etc. These products are eco-friendly and are widely demanded for their reliable features and durability.

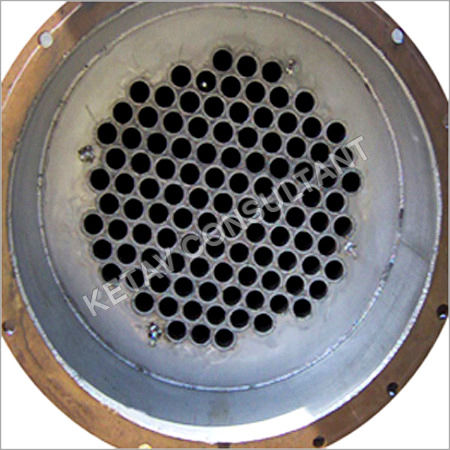

Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers offered by us in manufactured as per the quality standards laid by the industry. As a well known manufacturer and supplier, we are using high quality raw materials which are procured from reliable vendors of the market. Examined on various quality parameters, these products are acknowledged for their superior performance, fine finish, compact construction, reliability. Available at most competitive prices, these Shell and Tube Heat Exchangers are offered in various specifications and custom specified specifications.

Uses of Shell and Tube Heat Exchangers :

- Petrochemical industry

- Power plants

- Air conditioning unit

- Chemical Plants

Tubular Heat Exchanger

With our wide industrial experience and support of our dedicated team of professionals, we are engaged in serving our valued clients with a wide range of Tubular Heat Exchanger. We have succeeded to become one of the leading manufacturers and suppliers in the industry by offering products made in complete adherence with the industry set quality guidelines. Being manufactured by a diligent team of experts using quality approved raw materials, our products are flawless in nature. Furthermore, we employ advanced technologies to ensure superior quality. These Tubular Heat Exchangers are used in various industrial applications.

Product Features :

- Excellent strength structures

- High heat transfer tubular exchanger

- High flexible operations exchanger

- Toughness, light weight structure

Precision Engineering for Industrial NeedsEach Shell and Tube Heat Exchanger is manufactured with exacting standards, ensuring reliable operation within complex industrial environments. Ranging from 10 to 50 meters in width and compatible with voltages between 120 and 440 volts, these exchangers adapt seamlessly to diverse installation requirements. Their robust construction and advanced materials provide long-term performance and minimal maintenance.

Versatile Applications Across IndustriesDesigned for a broad spectrum of industrial applications, our Shell and Tube Heat Exchangers cater to chemical processing, power generation, pharmaceuticals, food and beverage, and more. Their adaptability, combined with dependable service support from our team in India, makes them an excellent choice for demanding operational settings.

FAQs of Shell and Tube Heat Exchangers:

Q: How are Shell and Tube Heat Exchangers typically used in industrial settings?

A: Shell and Tube Heat Exchangers are primarily used in industries for efficient heat transfer between fluids. They handle processes such as cooling, heating, condensation, and evaporation in sectors like chemical processing, power plants, and manufacturing.

Q: What are the voltage compatibility specifications for these heat exchangers?

A: These units are compatible with a voltage range of 120 to 440 volts, ensuring flexibility and suitability for a wide array of industrial power systems.

Q: When is it recommended to install a new Shell and Tube Heat Exchanger?

A: Installation of a new Shell and Tube Heat Exchanger is recommended when you require enhanced heat transfer efficiency, are upgrading outdated equipment, or expanding production capacity to meet increased demands.

Q: Where can these Shell and Tube Heat Exchangers be supplied from?

A: We supply Shell and Tube Heat Exchangers from India, serving clients as exporters, importers, manufacturers, service providers, and suppliers for global industrial needs.

Q: What is the manufacturing process for these heat exchangers?

A: The manufacturing process involves precision fabrication of shells and tubes, quality-controlled assembly, leak testing, pressure evaluations, and final inspection to meet stringent international standards.

Q: What benefits do these exchangers offer over other types?

A: Shell and Tube Heat Exchangers provide superior efficiency, robust construction, adaptability for large-scale industrial use, and are capable of handling high pressures and temperatures, contributing to lower operational costs and longevity.

Q: How does the width range (10-50 meters) affect their industrial usage?

A: The available width range allows customization to accommodate specific installation sites and processing volumes, making these heat exchangers well-suited for both compact and large-scale industrial applications.