Product Description

We hold vast acumen and expertise in manufacturing and supplying a qualitative range of Stainless Steel(SS) Heat Exchangers. The high grade stainless steel used in designing of these heat exchangers impart high strength and excellent corrosion & chemical resistance to them. These are widely being used in chemical, beverage and pharmaceutical industries. We offer these Stainless Steel(SS) Heat Exchangers in various sizes and specifications so as to meet the varied industrial demands.

Attributes:

- High efficiency function

- Low consumption power

- Easy installation facility

- Impeccable performance functioning

Product Features:

- Titanium tube

- Less solid fouling

- Less floor space require

- High exchange efficiency exchanger

- Excellent acidic resistance capacity

- Suitable for high intensified heat transfer capacity

Provided Stainless Steel Heat Exchangers include sanitary and industrial designs, pre-engineered, custom, embossed plate, frame and plate, cooling and heating coils, brazed plate, tube and shell.

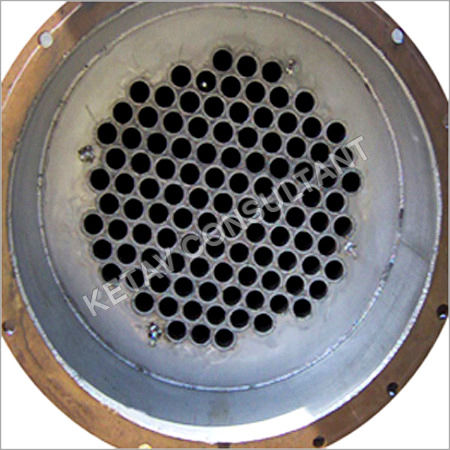

Shell & Tube :

These are made from untainted steel as well as are corrosion safe and can be made to meet different beverage, dairy, food, pharmaceutical and industrial demands. Different alloys and material including brass, carbon, steel and more are likewise accessible.

Brazed Plate:

Brazed plates are well known alternative with their minimal size and extended productivity plans as well as can be provided with plates and nickel or copper braze. The units are approximately six times littler than elective techniques for heat exchanger with similar limit.

Heating and Cooling Coils:

Loops are utilized in numerous applications, each possessing their own particular interesting difficulties. Our plate and different tube designs, enable our loops to effortlessly adjust and address such difficulties for replacement and new applications.

Plate & Frame :

Plate heat exchanger includes metal plates that are fixed with welded, gasket or some blend of both.

Embossed Plate:

Dimpled plates are intended for minimized spaces, profoundly adaptable boards that can be fitted, formed or soldered to suit customers correct needs from an assortment of materials comprising titanium, stainless steel and steel.

| Quick Buyer Details |

| Product Name | Stainless Steel Heat Exchangers |

| Product Code | SSEH |

| Brand Name | Ketav Consultant |

| Model Number: | SSEH |

| Business type | Manufacturers,Suppliers |

| FOB Price: | By Email |

| Place of manufacturer: | Ahmedabad,Gujarat,India |

| Mini Order Quantity | As per buyers order |

| Payment Terms | cash in advance, before shipment, pre-authorized payment, by credit card |

| Company Standard | unbeatable Quality |

| Technical Parameters: |

| Place of Origin: | Ahmedabad,Gujarat,India |

| Product Type: | Heat exchanger,stainless steel heat exchanger |

| Heat Exchanger Application: | Industrial,Heater Parts |

| Tube Type: | Smooth tube,thread tube |

| Voltage: | Customer specific requirements |

| Weight: | Customer specific requirements |

| Structure: | Tube Heat Exchanger,Plate Heat Exchanger |

| Power: | Customer specific requirements |

| Interface Material: | Carbon steel, stainless steel,galvanized sheel |

| Dimension(L*W*H): | NA |

| Price: | Competitive |

| Packaging & Delivery Details |

| Packaging Detail: | Packaging as per quality standard |

| Delivery Detail: | As Per Customer Specifications |

| Shipment By: | Cargo, Road, Sea |

Crafted from superior-grade stainless steel, our heat exchangers deliver long-lasting operation even in harsh industrial environments. The robust construction minimizes maintenance, while the corrosion-resistant properties help ensure consistent heat transfer efficiency throughout their lifespan.

Versatile Industrial UtilitySuitable for diverse industrial sectors, including chemical, power generation, and food processing, these heat exchangers offer flexible width and thickness options. Their adaptable design meets both standard and custom requirements, facilitating tailored integration into any facility.

FAQs of Stainless Steel Heat Exchangers:

Q: How are stainless steel heat exchangers installed and maintained in industrial settings?

A: Installation typically involves securely connecting the unit to both hot and cold process flows, ensuring proper alignment and tight sealing. Regular maintenance such as descaling and inspections for wear ensures the exchanger operates efficiently, minimizing downtime.

Q: What benefits do stainless steel heat exchangers offer compared to alternatives?

A: Stainless steel models provide excellent resistance to corrosion, high temperature tolerance, and low maintenance needs. These advantages lead to a longer lifespan and greater energy efficiency, making them ideal in demanding industrial environments.

Q: When should I consider replacing my existing heat exchanger with a new stainless steel model?

A: Replacement is advisable when you notice persistent drops in heat transfer efficiency, corrosion, or leakage. Upgrading to a new stainless steel heat exchanger improves operational reliability and energy savings.

Q: Where are your stainless steel heat exchangers supplied and serviced in India?

A: We supply and service our stainless steel heat exchangers across all major industrial regions in India, ensuring prompt delivery, installation, and technical support for a seamless customer experience.

Q: What is the typical process involved in procuring your heat exchangers?

A: Begin by contacting our team to discuss your application needs. We assist with model selection, customization options, and provide detailed quotations. Production, quality tests, and delivery follow, along with on-site support if required.

Q: How can these heat exchangers be utilized in different industry sectors?

A: These units are versatile, enabling precise temperature control in sectors such as power generation, chemical manufacturing, pharmaceuticals, and food processing by transferring heat between fluids safely and efficiently.